Time: 1 September 2021 |

Source: Acrel

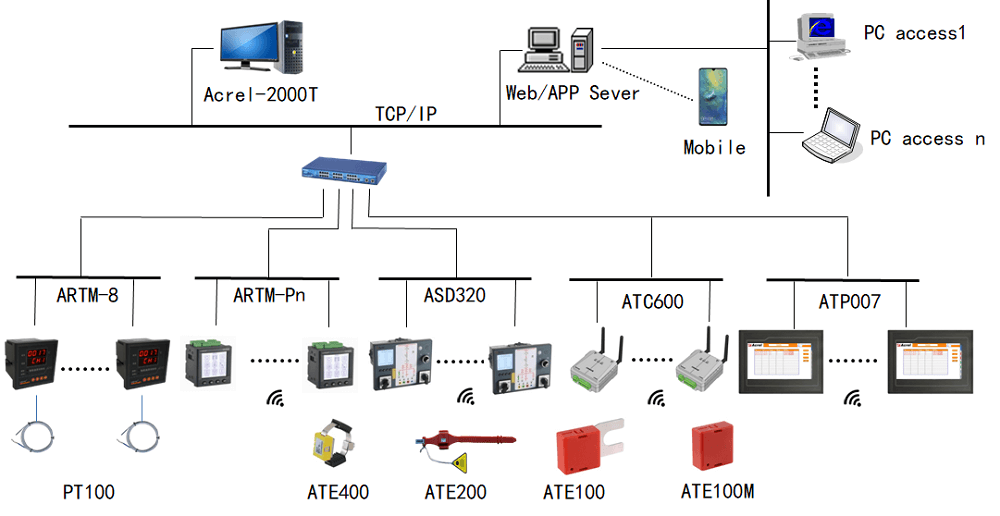

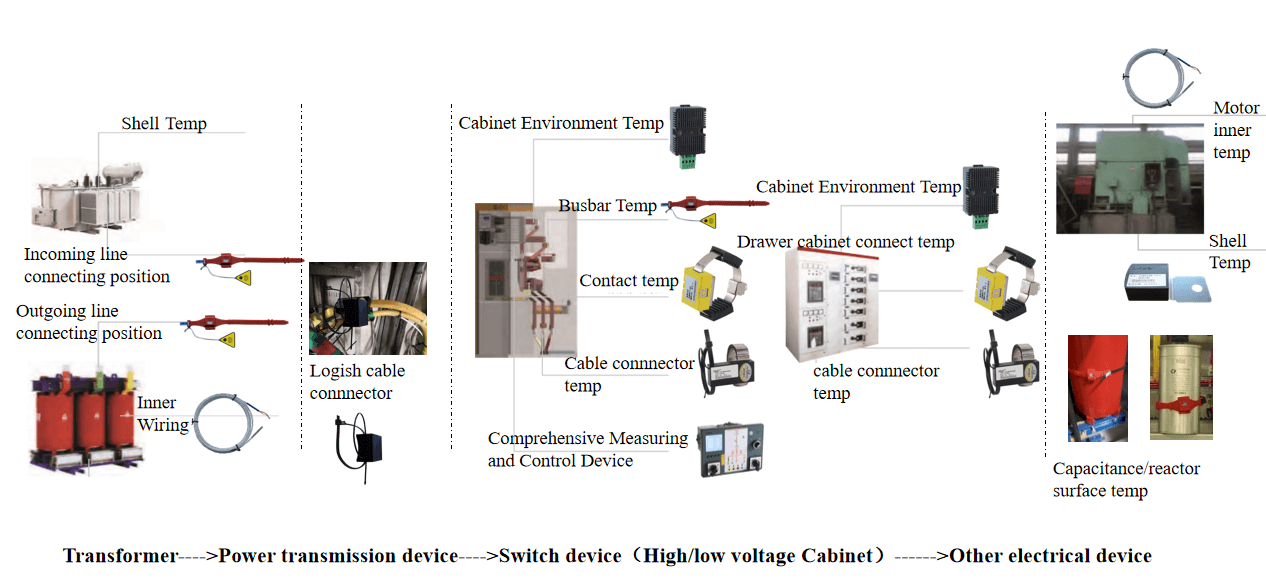

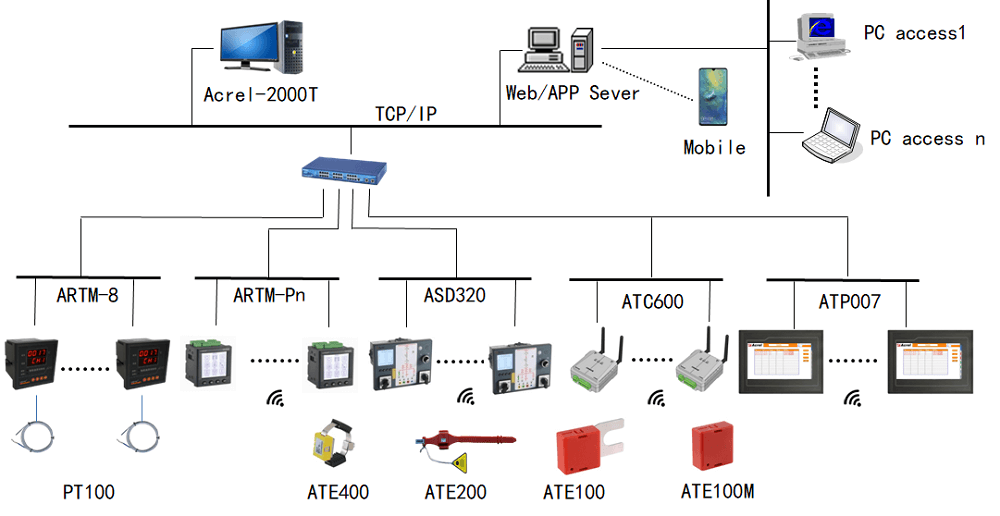

Abstract: With the development power industry,the requirements for the safety and reliability of equipment are getting higher and higher. In this situation,ACREL wireless temperature monitoring system is designed for high voltage device. This technology is to install the temperature sensor with built-in battery or temperature sensor by current sensing and wireless transmitter module at each temperature measurement point. The sensor periodically sends the temperature measurement data wireless to the receiving unit, and the receiving unit can be connected to the network to send the data to the master station, thereby realizing electrical temperature monitoring of a regional system.

This article introduce wireless monitoring system used in substations in Netherlands.

1.Current Status

For many years, due to the limitations of the technical level, although infrared thermometer, infrared imager, temperature sensing cable, traditional point-type temperature measurement system have been used to solve the above problems, but can not achieve the switch cabinet such as circuit breaker, the connection point and contact temperature measurement.

At present, domestic electric temperature measurement mainly uses infrared point measuring instrument and optical fiber temperature measuring instrument. However, the on-line method cannot solve the problem of high-voltage insulation, so the electrical equipment with limited space, such as the contact of high-voltage switch, basically operates in a completely unmonitored state, with major safety hazards.

2.Project Overview

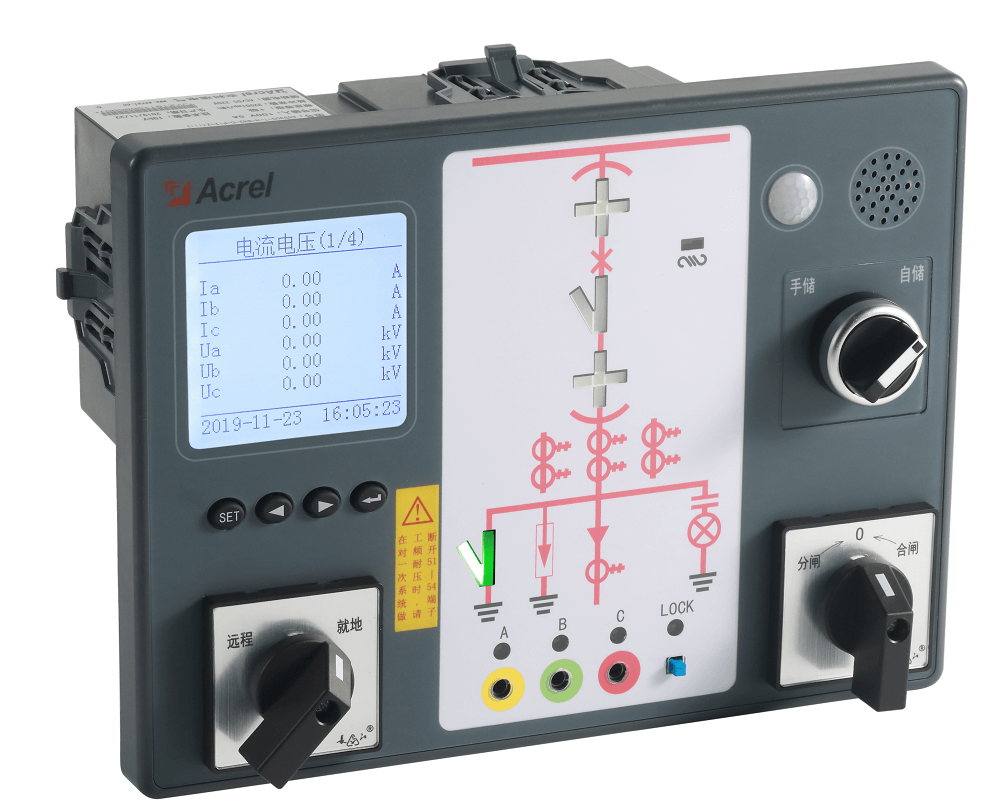

DigIoT is an electric IoT company, providing electrical IoT services for local substations. Customer consults Acrel wireless temperature measurement products, attending through Acrel ATE wireless temperature sensor and ATC receiver, the cable in the switchgear temperature detection, And through RS485 communication data transmission to the back platform for real-time monitoring, can effectively prevent overheating failure, affect the normal operation of equipment, avoid safety risks.

3.Wireless temperature monitoring device Introduction

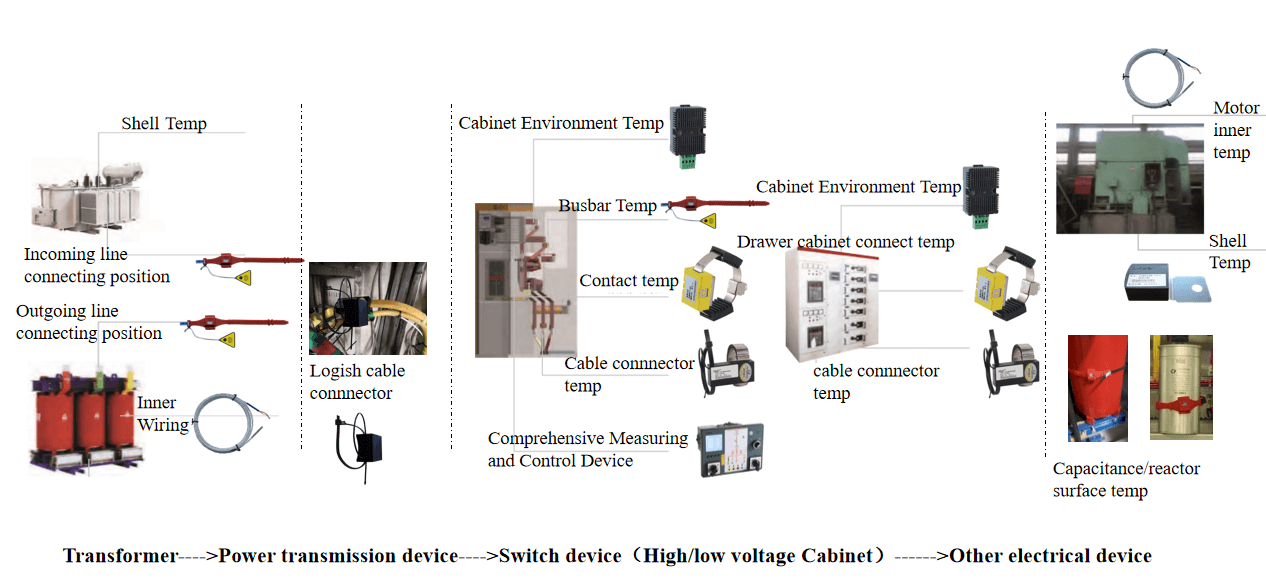

Acrel on-line temperature measurement device is suitable for the temperature detection of high and low voltage switches, circuit breaker contacts, high voltage cable middle heads, low voltage and high current equipment, to prevent contact caused by oxidation, loosening and other factors during operation Excessive contact resistance and heat generation become a safety hazard, timely, continuous and accurate reflection of equipment operating status, and equipment safety.

3.1 Wireless Temperature Measurement Scheme

1.Temperature measuring instrument

1) Temperature sensor

a.Battery-powered wireless temperature sensor

sensor installed in a heating area that collects temperature and transmits it wirelessly.

There are currentlyfour type wireless temperature sensors:

Name | Shape | Parameter instruction | Installation |

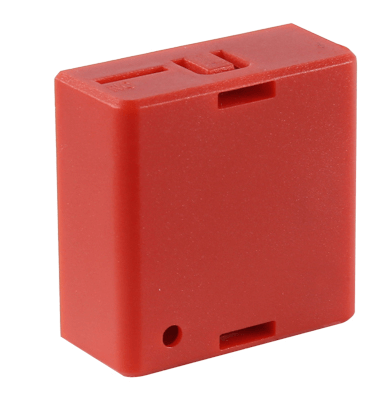

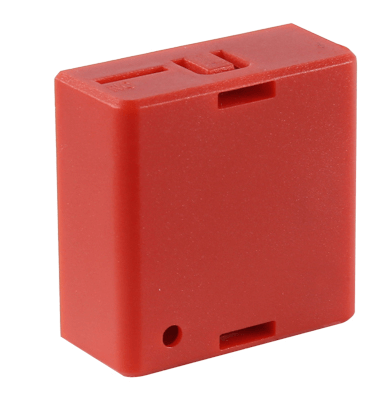

ATE100M |

| 32.4*32.4*16mm( L*W*H, aperture);-50℃~+125℃, Accuracy Class ±1℃, battery powered, life ≥5 years ; 470MHz, open distance 150m. | Magnetic fixed |

ATE100 |

| 62.4*32.4*16mm,φ13.5mm(L*W*H, aperture);-50℃~+125℃, Accuracy class ±1℃, battery powered, life ≥5 years ; 470MHz, open distance 150m. | Bolt fixed |

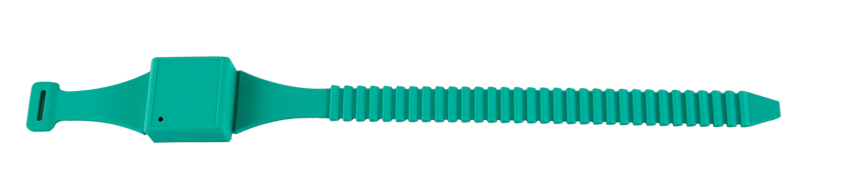

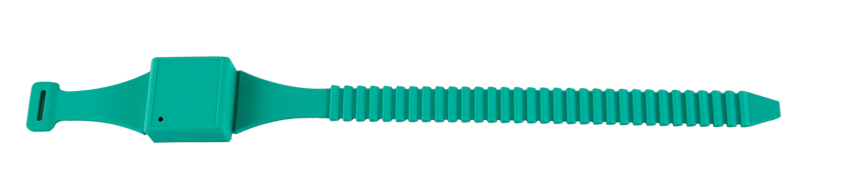

ATE200 |

| 35*35*17mm, L=330mm (L*W*H, belt);-50℃~+125℃, Accuracy Class ±1℃, battery powered, life ≥5 years ; 470MHz, open distance 150m. | Strap binding |

ATE100P |

| 62.4*32.4*16mm,φ13.5mm(L*W*H, aperture);-50℃~+125℃, Accuracy class ±0.5℃, battery powered, life ≥5 years ; 470MHz, open distance 150m. IP68 | Outdoor bolt fixed |

ATE200P |

| 35*35*17mm, L=330mm (L*W*H, belt);-50℃~+125℃, Accuracy Class ±0.5℃, battery powered, life ≥5 years ; 470MHz, open distance 150m.IP68 | Outdoor strap binding |

b.CT induction radio wireless temperature sensor

sensor installed at a high current such as a circuit breaker contact, a bus bar, a cable lap contact, to collect temperature and transmit it wirelessly.

There are currently two wireless temperature sensors:

Name | Shape | Parameter Instruction | Installation |

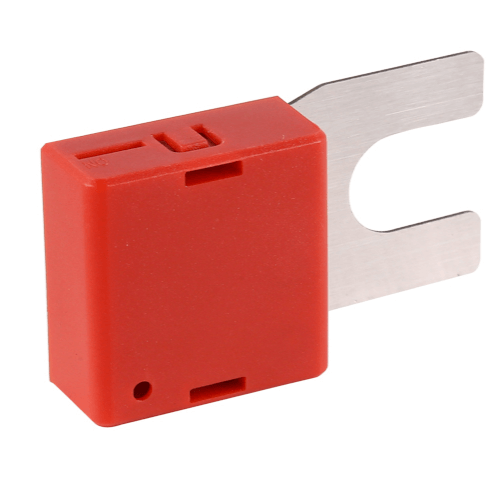

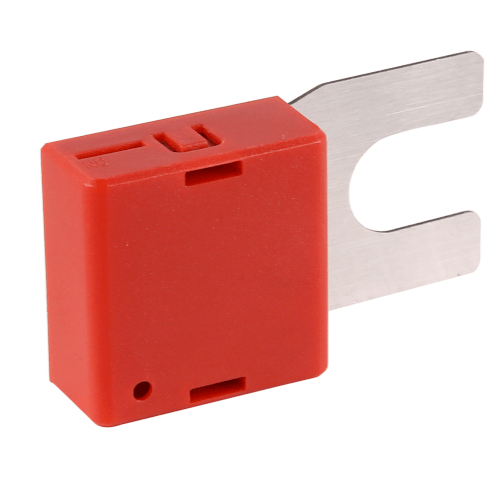

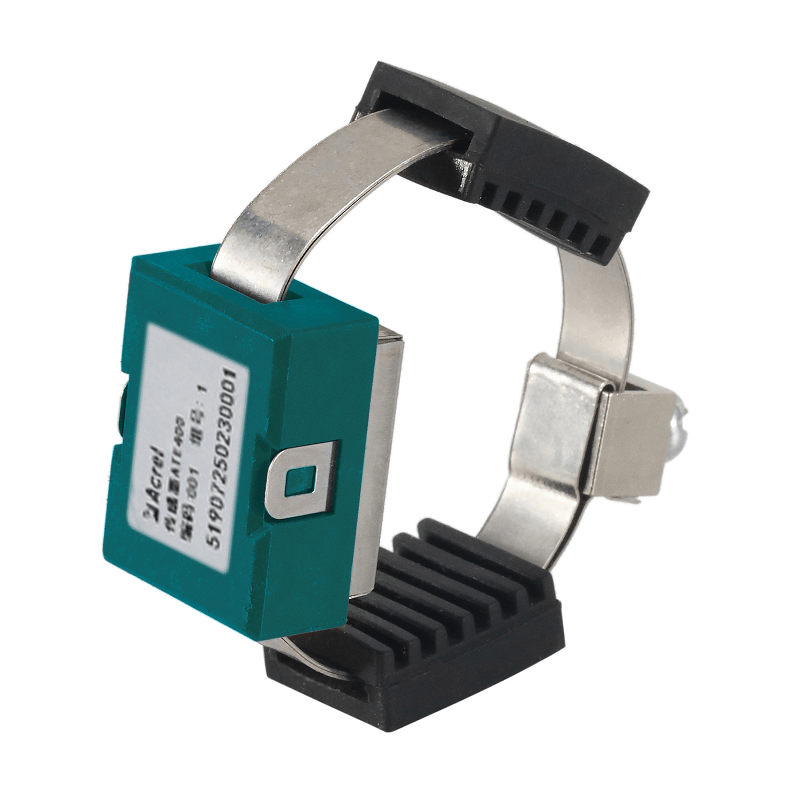

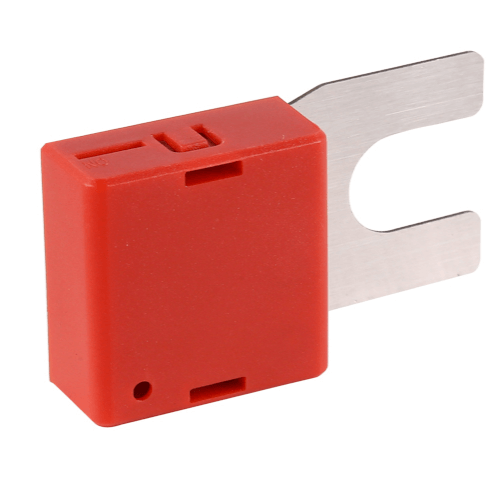

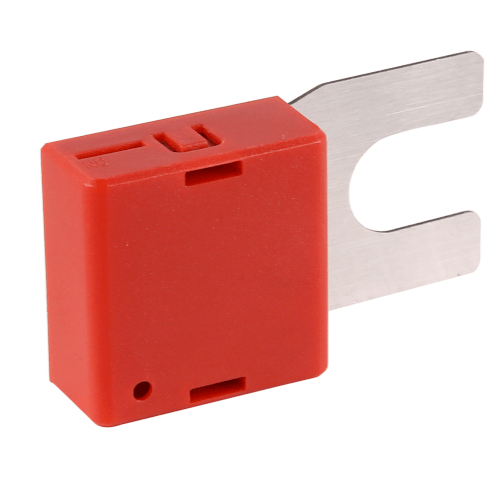

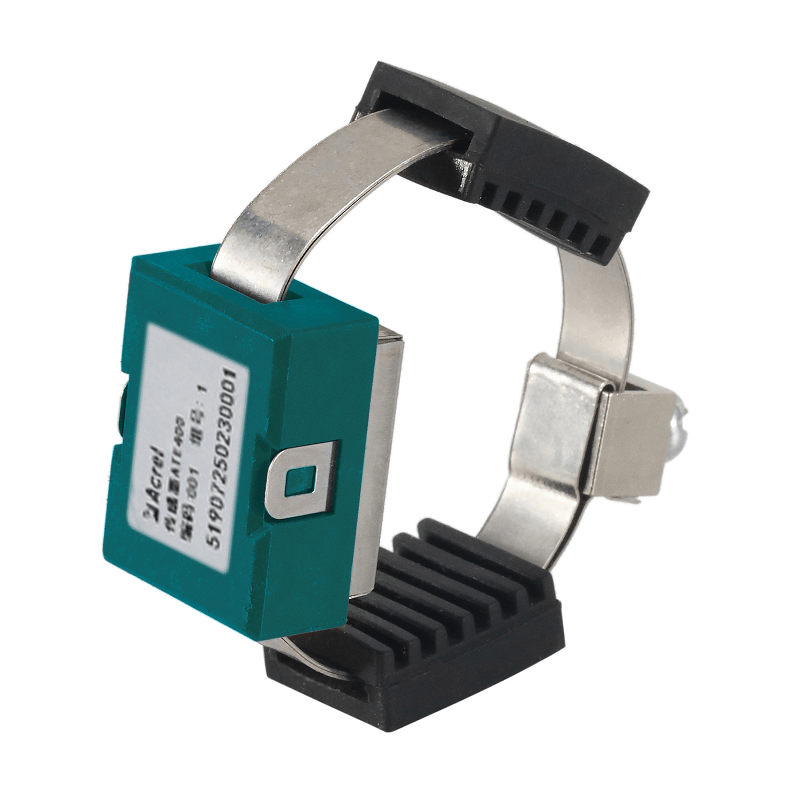

ATE400 |

| 25.82*20.42*12.8mm(L*W*H); -50℃~+125℃, Accuracy class ±1℃, CT induction of electricity powered, starting current ≥5 A; 470MHz, open distance 150 m. | Alloy sheet fixed; CT Powered |

2) Receiving /displaying unit

a. Receiving unit

Name | Shape | Parameter Instruction | Installation |

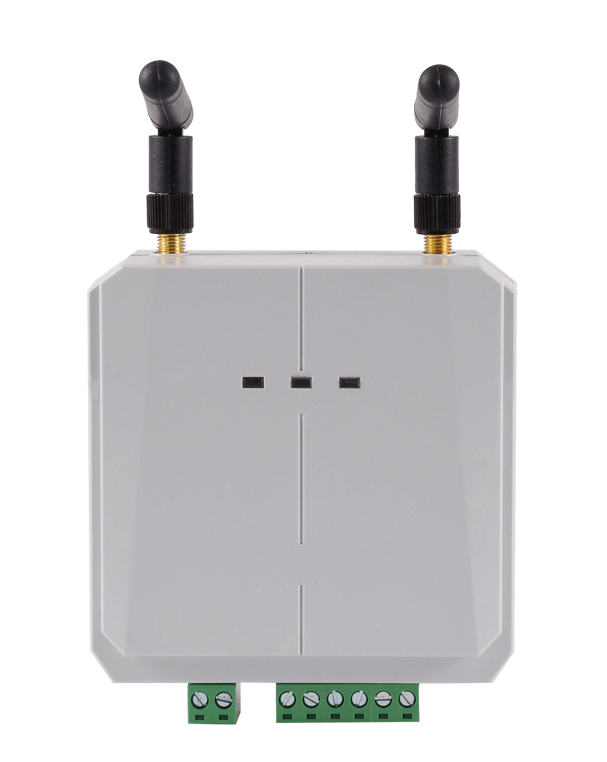

ATC450-C |

| 65*45*28mm(L*W*H); DC24V power supply; RS485 interface; Modbus protocol. receive 60 ATE temp. sensor temperatures; | 35mm DIN rail screws fixed (φ4,36mm) |

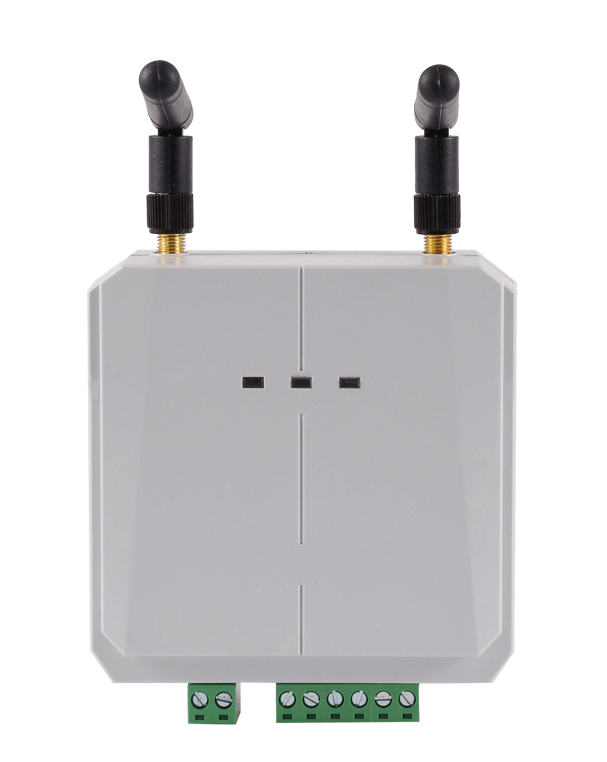

ATC600 |

| 90*90*38mm(L*W*H); AC/DC 85~265V power supply; 1 channel uplink RS485; Modbus protocol; Can receive 240 ATE wireless temperature sensors; | 35mm DIN rail |

b. Displaying Unit

Name | Shape | Parameter Instruction | Installation |

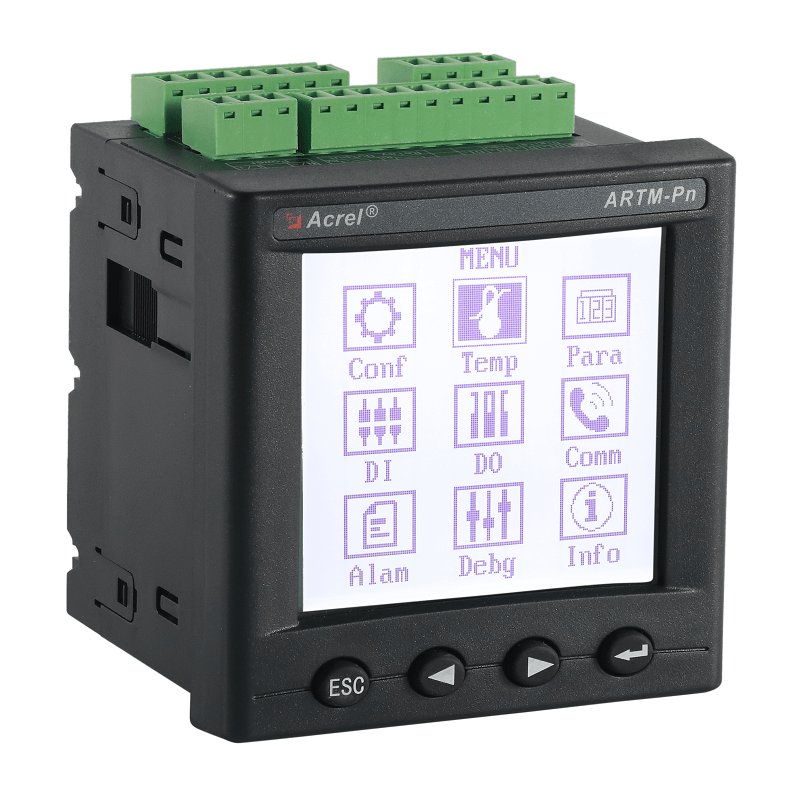

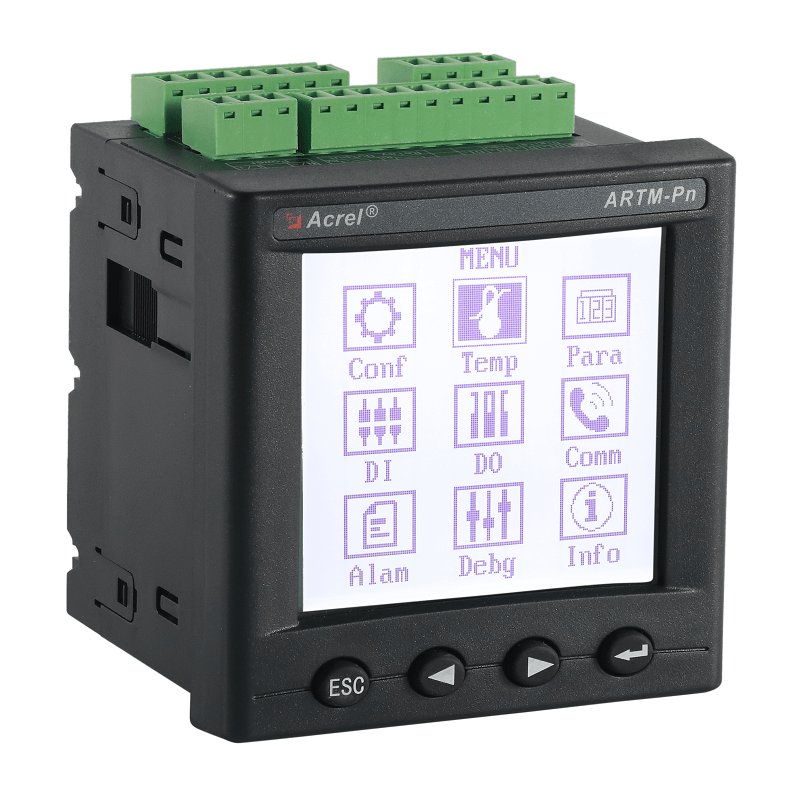

ARTM-Pn |

| Panel 96*96*17 mm, depth 65 mm, opening 92*92 mm, AC85-265V or DC100-300V power supply; RS485 interface; Can receive 60 ATE wireless temperature sensors; Modbus protocol. | Embedded panel installation |

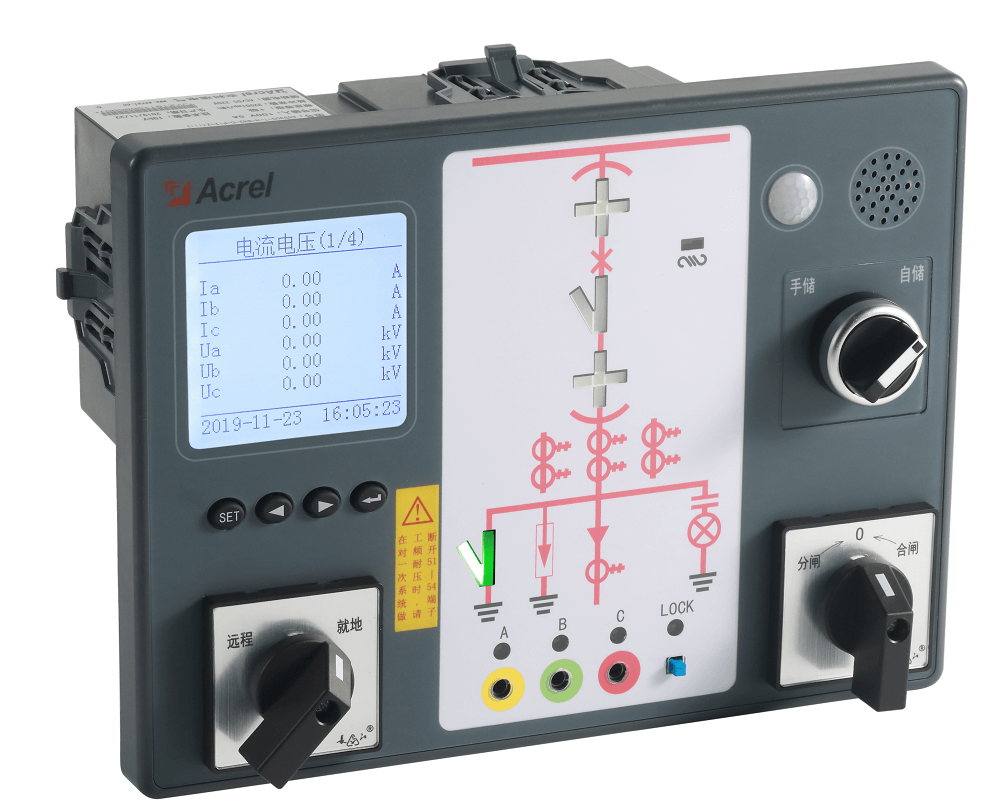

ASD300/320 |

| Panel 237.5*177.5*15.3 mm, depth 67 mm, Cut-out size 220*165 mm; AC85-265V or DC100-300V power supply; RS485 interface; Can receive 12 wireless temperature sensors; Modbus protocol. | Embedded panel installation |

ATP007 |

| Panel 226.5*163*6 mm, depth 70 mm; hole 215*152 mm; DC24V power supply; can receive 4 ATC450-C or 1 ATC600. 1 channel uplink RS485 interface, 1 channel downlink RS485; | Embedded panel installation |

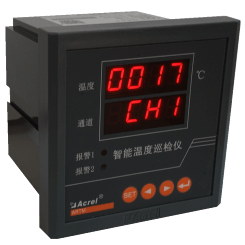

ARTM-8 |

| Panel 96*96*12.5 mm, depth 70 mm, hole 88*88 mm; along the way RS485 interface, can be connected to 8 channels of temperature sensor; Modbus Protocol | Embedded panel installation |

Acrel-2000T/A |

| Cabinet size: 480/420/200mm; DC220V power supply; 1 channel uplink RS485, the downlink is one Ethernet port, and 4 sets ATC450-C or 1 set ATC600 can be received | Wall mounted |

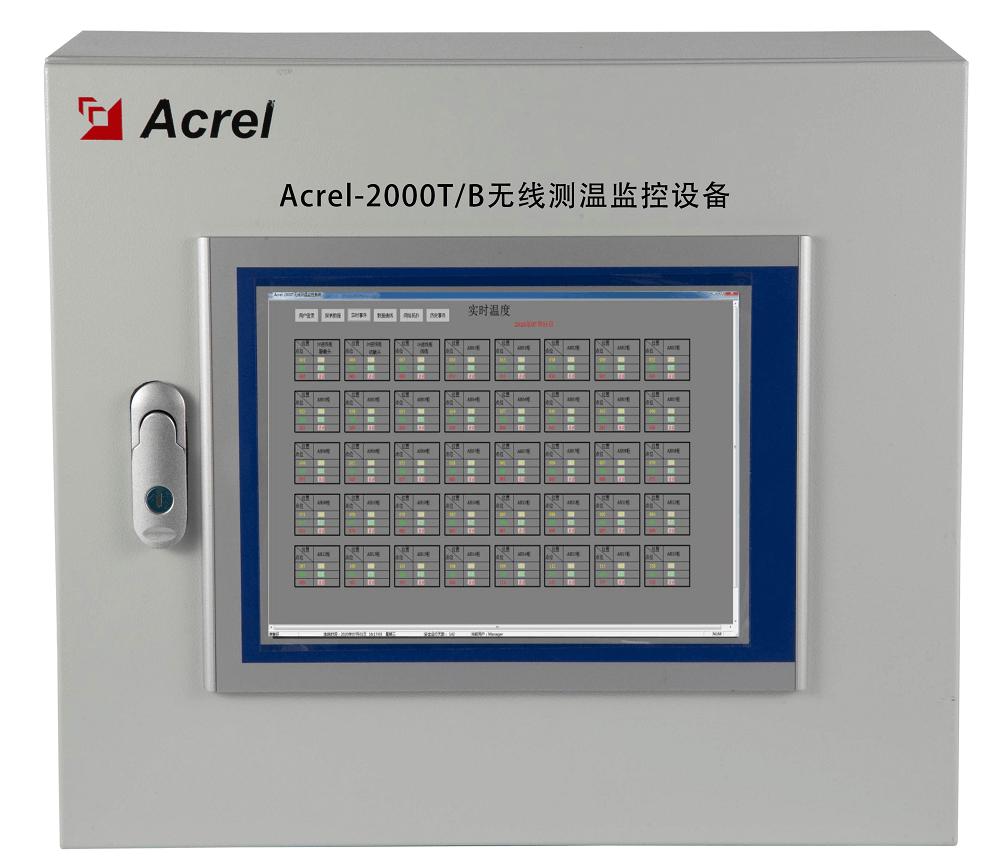

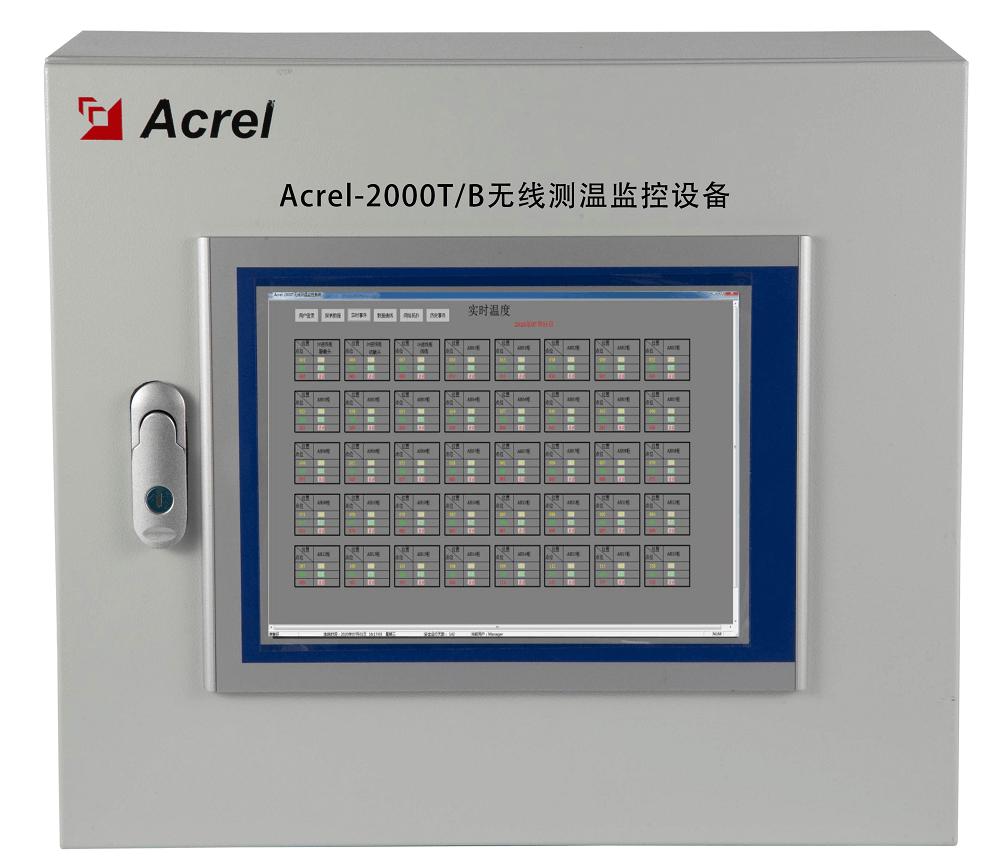

Acrel-2000T/B |

| The size of the cabinet is 480/420/200mm; Hardware: memory 4G, hard disk 128G, Ethernet port; Displayer: 12 inches, resolution 800/600; operating system: Windows 7; database system: Microsoft SQL Server 2008 R2; I/O interfaces: GLAN×2, USB×4, COM×6; Optional Web platform/ APP server | Wall mounted |

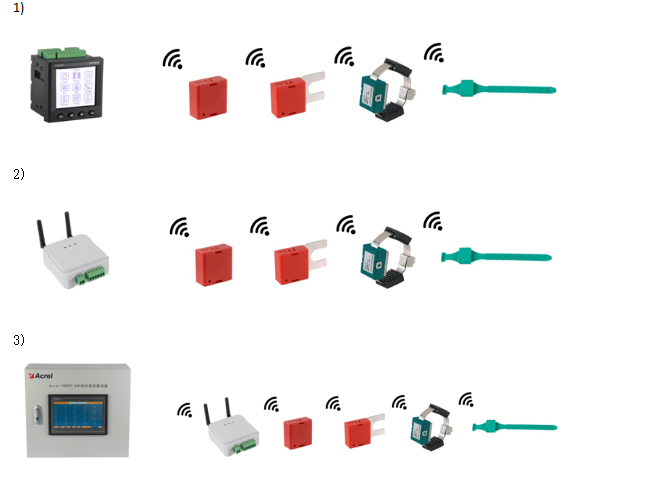

3.2 Structure

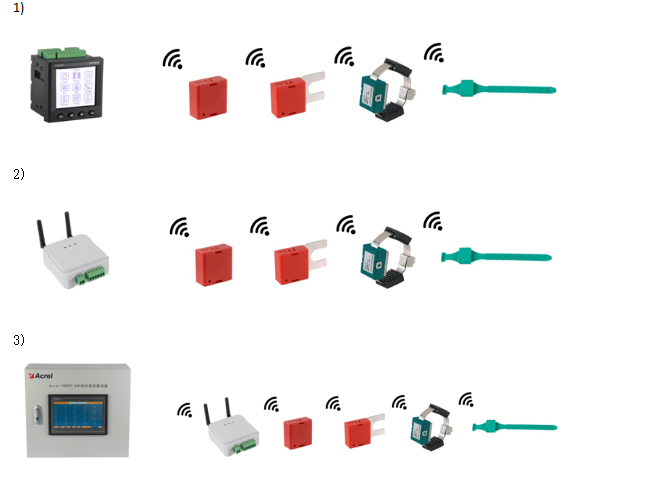

3.3 Typical Solution

4.Typical Application

Bibliography

1、Solutions for enterprise micro-grid system

Back To The List

![]()

![]()

.png)

.png) EN

EN